Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

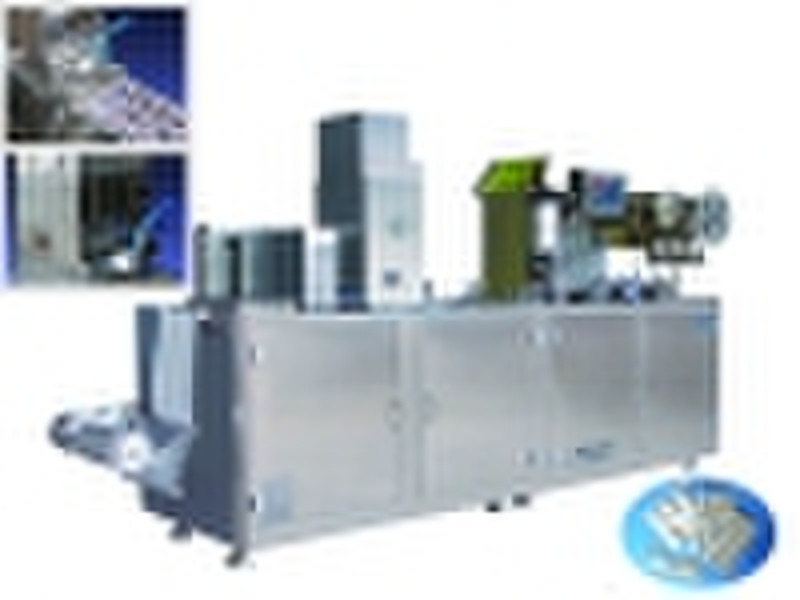

hard Alu/Alu Blister Packing Machine

Abby Ying

Contact person

Basic Information

This blister packing machine adopts the internationally popular composite aluminum film with such performance of good seal,moisture proof and light proof as forming material.It can cold punch stiff and uniform blister through special forming mould.And it can produce beautiful packing products through such stations as professional feeding system,detecting heat sealing,batch No. printing ,lin cutting ,blanking,wasted plate automatic rejecting,waster automatic reconery finished product conveying etc. Main characteristics : cold punching forming moulds makes blister stiff and uniformhuman-machine interface,PLC control,variable frequency stepless speed regulatingprofessional feeder,adopting feeding method of multi-stage vibration,pipeline baiting ,register and position-checkingautomatically detect missing tablets (pellets),and automatically reject waste platecan be equipped with cursor GC register devicewith cylinder heat-sealing ,the upper and nether checkers ensure the effect of heat-sealing,and waster automatically recovering device. Main techinical parameter: Punching frequency 15-25 time/minPunching plate4 plate/hour(standard)Adjustable scope of travel30-120 mmMax forming area and depth245×112×18mmproductivity3600-6000 plate/hourTotal powerThree phase four wire 380V 50Hz 5.5 kwSpecification of packing material -----composite Alu Foil250×0.15mmSpecification of packing material -------heat-sealing Alu Foil PTP250×0.02mmAir-compressor≥0.22m3/min self-prepared)pressure0.5-0.7MpaOverall demension2800×830×1900mmPackaging dimension3540×720×1990mmWeight1500kg

Delivery terms and packaging

Packaging Detail: standard wooden case Delivery Detail: within 30 days after the first payment

Port: shanghai port

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: